Product Description

Product Description

|

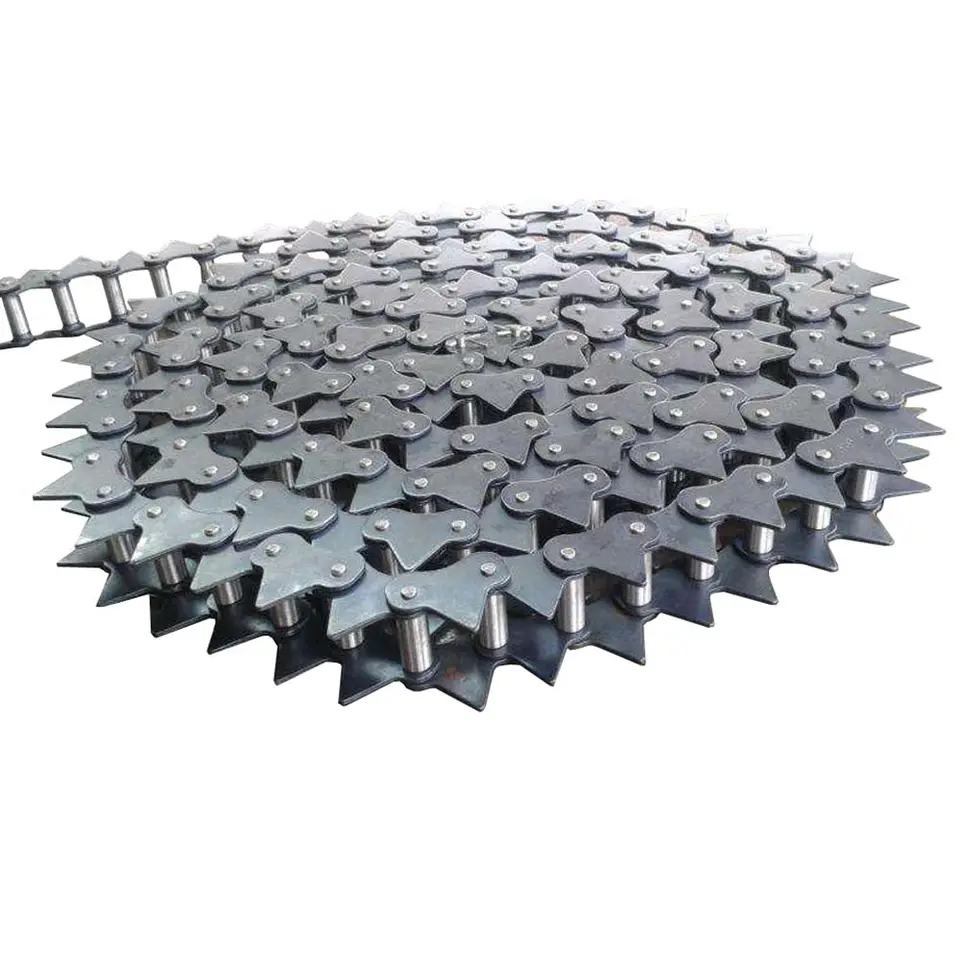

HRSY Roller Chain Profile |

|||

|

Standard: |

ANSI, DIN, ISO |

||

|

Type: |

Drive chains, Conveyor chains, Engineering chains, Agricultural chains, Traction chains, Escalator chains |

||

|

Drive chain |

Short pitch precision roller chain (A series, B series, Hevey duty series roller chain) High strength short pitch roller chains Self-lubrication roller chain O-Ring chains Oil filed chains Heavy duty cranked-link transmission chains Double pitch transmission chains Inverted tooth chains Motorcycle chains Other (Driver chains) |

||

|

Conveyor chains |

Conveying roller chains Rubber attached plate chains Printing iron drying room line chains Double hinged conveyor chains Metric (M type) conveyor chains FV series conveyor chains Wooden conveyor chains Chains for food packaging machinery Conveyor chains for paper roll |

||

|

Engineering chains |

Conveying chains for cement industry Scraper conveyor chains Conveyor chains for coal washer Rubber gloves carrier chains Steel sleeve chain for engineering Welded-steel-type mill chains Sugar machine chains Conveyor chains for steel mill |

||

|

Agricultural chains |

Agricultural machinery drive chains Steel pintle chains ZGS38 combine harvester chains Rice harvester chains S type C type Others |

||

|

Traction chains |

Plate chains Leaf chains for sky stacker Traction chains Others |

||

|

Escalator chains |

Escalator step chains Escalator driver chains |

||

|

Material |

40Mn, 45Mn, SS316, SS304, SS201 |

||

|

Advantage |

We have competitive price and high quality. Our stock standard length: 5ft each piece, 10ft each piece. Custom length: We can custom according to your demand. We can accept your Logo, accept ODM, OEM. |

||

Detailed Photos

Packaging & Shipping

Company Profile

ZheJiang Haorongshengye Electrical Equipment Co., Ltd.

1. Was founded in 2008

2. Our Principle:

“Credibility Supremacy, and Customer First”

3. Our Promise:

“High quality products, and Excellent Service”

4. Our Value:

“Being Honesty, Doing the Best, and Long-lasting Development”

5. Our Aim:

“Develop to be a leader in the power transmission parts industry in the world”

|

6.Our services: |

1).Competitive price |

|||

|

2).High quality products |

||||

|

3).OEM service or can customized according to your drawings |

||||

|

4).Reply your inquiry in 24 hours |

||||

|

5).Professional technical team 24 hours online service |

||||

|

6).Provide sample service |

||||

Main products

Machines

Exbihition

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery, Car |

| Surface Treatment: | Oil Blooming |

| Structure: | Roller Chain |

| Material: | Stainless Steel |

| Type: | Short Pitch Chain |

| Samples: |

US$ 50/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the factors to consider when selecting the right agricultural chain pitch?

Choosing the appropriate agricultural chain pitch is crucial to ensure optimal performance and longevity in farming equipment. Several factors should be taken into account when making this selection:

- Application Requirements: Understand the specific requirements of the agricultural application in which the chain will be used. Consider factors such as the type of equipment, load capacity, and the frequency of use.

- Power Transmission: Determine the power transmission needs of the machinery. Higher horsepower or torque requirements may call for a larger chain pitch to handle the increased load.

- Speed: Consider the operating speed of the agricultural equipment. Higher speeds may require smaller chain pitches to ensure smooth operation and reduced wear.

- Working Conditions: Evaluate the environmental conditions in which the chain will operate. Dust, dirt, moisture, and other contaminants can impact chain performance and durability.

- Load Distribution: Analyze how the load is distributed across the chain. Uniform load distribution is essential for preventing premature wear and maintaining the integrity of the chain.

- Maintenance: Factor in the maintenance requirements of the chain pitch. Smaller pitches might require more frequent lubrication and inspection, while larger pitches may offer more tolerance to contamination.

- Compatibility: Ensure that the selected chain pitch is compatible with the sprockets and other components in the agricultural machinery.

- Cost-Effectiveness: Strike a balance between the initial cost of the chain and its expected lifespan. Choosing a high-quality chain that meets the application needs can lead to cost savings in the long run.

By considering these factors, farmers and equipment operators can make an informed decision when selecting the right agricultural chain pitch. Properly matching the chain to the specific application and operational requirements will contribute to enhanced equipment performance, reduced downtime, and increased overall productivity in farming operations.

What are the best practices for maintaining agricultural chains?

Maintaining agricultural chains is essential to ensure their longevity, reliability, and optimal performance in farming operations. Here are some best practices for maintaining agricultural chains:

- Regular Inspection: Conduct routine visual inspections of the chains to check for signs of wear, damage, or misalignment. Look for elongation, corrosion, and broken links.

- Lubrication: Proper lubrication is crucial for reducing friction and wear. Follow the manufacturer’s guidelines to apply the right type and amount of lubricant regularly.

- Tension Adjustment: Maintain the correct tension in the chains. Loose chains can lead to jumping or skipping, while overtightened chains can cause premature wear.

- Cleanliness: Keep the chains clean and free from debris, dirt, and crop residues that can cause abrasive wear and damage.

- Environmental Protection: Store agricultural equipment in a dry and covered environment when not in use to prevent rust and corrosion.

- Replacement of Worn Parts: Replace any worn-out or damaged components, such as sprockets, pins, and bushings, as they can affect chain performance.

- Proper Use: Operate agricultural machinery within recommended loads and operating conditions to avoid excessive stress on the chains.

- Training and Operator Awareness: Train equipment operators on proper chain maintenance and raise awareness of the importance of regular inspections and care.

By adhering to these best practices, farmers and agricultural equipment operators can maximize the lifespan of their agricultural chains and minimize downtime due to chain-related issues. Regular maintenance not only enhances chain performance but also contributes to the overall efficiency and productivity of farming operations.

What is an agricultural chain and what is its role in farming equipment?

An agricultural chain is a type of roller chain specifically designed for use in farming equipment and agricultural machinery. It plays a crucial role in the operation of various farming equipment, ensuring the efficient transfer of power and motion in agricultural applications.

The role of agricultural chains in farming equipment includes:

- Power Transmission: Agricultural chains are primarily used for power transmission in farming machinery. They transmit rotational power from one part of the equipment to another, enabling the movement of various components such as wheels, conveyors, and cutting blades.

- Drive Systems: In tractors and other agricultural vehicles, agricultural chains are often used as part of the drive systems. They transfer power from the engine to the wheels or tracks, allowing the vehicle to move across the field with ease.

- Harvesting and Threshing: In harvesting machinery like combine harvesters, agricultural chains are responsible for driving the harvesting mechanism and threshing units. They enable the cutting and separation of crops from the stems and husks efficiently.

- Conveyors and Elevators: Agricultural chains are used in conveyor systems and elevators within grain handling equipment. They facilitate the movement of crops, seeds, and grains from one point to another during the storage and transportation process.

- Tillage and Planting: Agricultural chains are also used in tillage equipment and planting machines. They help in turning the soil, preparing the seedbed, and distributing seeds evenly during planting operations.

- Baling and Hay Handling: For equipment involved in baling and hay handling, agricultural chains assist in the compression and formation of bales, as well as in the movement of hay and straw.

Due to their robust construction and resistance to wear, agricultural chains can withstand the demanding conditions of agricultural environments, including exposure to dirt, debris, and harsh weather. Proper maintenance and lubrication are essential to ensure the longevity and reliable performance of agricultural chains in farming equipment.

editor by CX 2024-05-06

by

Leave a Reply